So, you’re thinking about ISO certification for your business? Maybe you’re in manufacturing, IT services, healthcare, logistics, or construction, and you’ve heard that getting ISO certified can give your company a competitive edge. But what’s the deal with ISO, and how do you actually get there? Let’s walk through the process together—step by step, no fluff, just the real stuff. It’s not as daunting as it seems, and by the end, you’ll see why it’s worth the effort. Ready? Let’s get started.

What’s ISO Certification, Anyway?

Before we jump into the how-to, let’s clear up what ISO certification is. ISO, or the International Organization for Standardization, sets globally recognized standards for quality, safety, and efficiency. Think of it like a universal handshake—your business proves it meets a certain level of awesomeness, and customers, partners, and even employees trust you more. Whether you’re building medical devices, coding software, or moving goods across continents, ISO standards like 9001 (quality management) or 14001 (environmental management) show you mean business.

Why does this matter? Because in industries like manufacturing or healthcare, customers don’t just want promises—they want proof. ISO certification is that proof. It’s like a badge that says, “We’ve got our act together.” Plus, it can open doors to new markets, especially if you’re eyeing international clients who love seeing those three letters: I-S-O.

Step 1: Pick the Right ISO Standard

First things first—you need to choose the ISO standard that fits your business. This isn’t a one-size-fits-all deal. If you’re in manufacturing, ISO 9001 is probably your go-to for quality management. Running an IT services company? ISO 27001 for information security might be your jam. Healthcare folks often lean toward ISO 13485 for medical devices, while logistics and construction might vibe with ISO 14001 for environmental responsibility.

Here’s the thing: picking the right standard feels like choosing a new phone. You don’t just grab the shiniest one—you figure out what fits your needs. Talk to your team, look at your industry, and maybe even chat with a consultant to nail this down. Getting this step right saves you headaches later. Ever bought the wrong tool for a job? Yeah, it’s like that—frustrating and costly.

Step 2: Get Everyone On Board

Once you’ve got your standard, it’s time to rally the troops. ISO certification process isn’t just a management thing—it’s a company-wide effort. From the folks on the factory floor to the coders in the back office, everyone needs to know what’s up. Why? Because ISO is about processes, and processes involve people. If your team doesn’t buy in, you’re pushing a boulder uphill.

Start with a kickoff meeting. Explain why ISO matters—maybe it’s about winning bigger contracts or making your workplace safer. Be real with them. Share stories of how sloppy processes can lead to costly mistakes, like a shipment going to the wrong city or a software bug causing a client meltdown. Paint a picture of how ISO can make everyone’s life easier, not harder. And don’t just talk at them—listen. What do they think needs fixing? Their input is gold.

Step 3: Map Out Your Current Processes

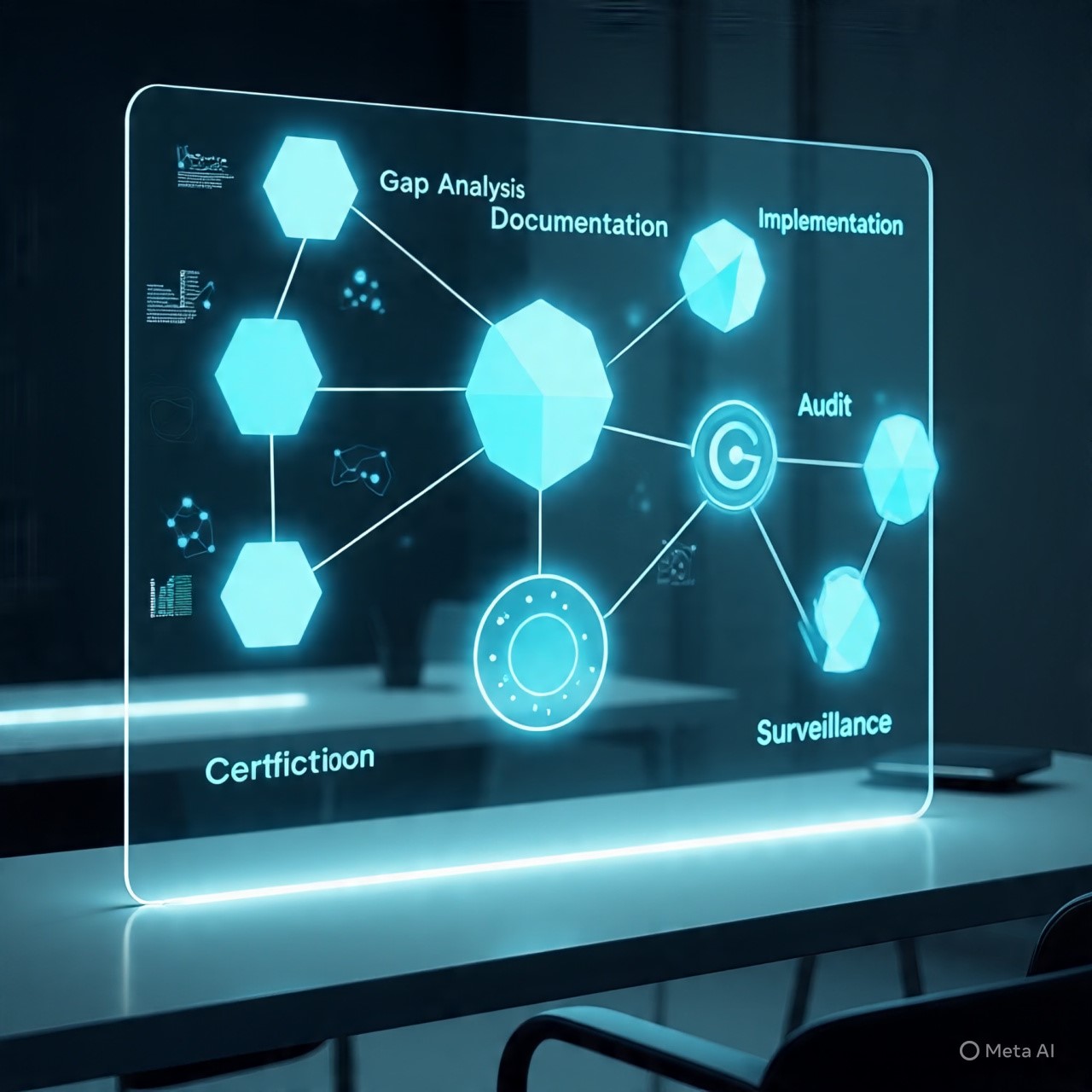

Now comes the part where you roll up your sleeves: figuring out what you’re already doing. This is called a gap analysis, but don’t let the jargon scare you—it’s just a fancy way of saying, “What’s working, and what’s not?” You’re basically taking a hard look at your processes—how you build products, deliver services, or manage risks—and comparing them to the ISO standard.

Grab a notebook or a spreadsheet and start documenting. How do you handle customer complaints? What’s your quality control process? If you’re in logistics, how do you ensure trucks are loaded safely? If you’re in IT, how do you protect sensitive data? Be brutally honest. It’s like cleaning out your garage—you might find some junk you didn’t know was there, but that’s okay. Knowing is the first step to fixing.

A Quick Tip for the Overwhelmed

Feeling a bit swamped? That’s normal. Mapping processes can feel like untangling Christmas lights. If it’s too much, consider bringing in an ISO consultant. They’re like the friend who’s really good at puzzles—they’ll help you see the big picture without losing your mind.

Step 4: Build (or Tweak) Your System

Here’s where the magic happens. Based on your gap analysis, you’ll start building or tweaking your processes to meet the ISO standard. This might mean creating new workflows, updating training programs, or setting up better ways to track performance. For example, a construction company might tighten up safety protocols, while a healthcare provider might streamline how they document patient care.

Don’t try to reinvent the wheel. Use what’s already working and make it better. If you’re in manufacturing, maybe you’ve got a solid quality check system but need better documentation. In IT, you might have great coders but need clearer protocols for handling data breaches. The goal is consistency—making sure everyone’s singing from the same hymn sheet.

And here’s a little secret: this step can be fun. It’s like giving your business a glow-up. You’re not just checking boxes for ISO; you’re making your company sharper, smoother, and more reliable. Who doesn’t want that?

Step 5: Train Your Team

You’ve got your shiny new processes—now it’s time to make sure everyone knows how to use them. Training is huge. Without it, your ISO efforts are like a car without gas—pretty, but not going anywhere. Set up workshops, create cheat sheets, or even make short videos if you’re feeling fancy. The goal is to make sure everyone, from the CEO to the intern, knows their role.

For example, in logistics, train drivers on new safety checks. In healthcare, make sure nurses understand updated record-keeping rules. Keep it practical and hands-on. People learn better when they can see how it applies to their daily grind. And don’t forget to keep the vibe positive—nobody likes a boring training session.

Step 6: Test the Waters

Before you call in the auditors, do a dry run. This is called an internal audit, and it’s like a dress rehearsal for the big show. Go through your processes with a fine-tooth comb. Are you meeting the ISO requirements? Are there any weak spots? Maybe your construction team forgot to log safety inspections, or your IT crew isn’t documenting software updates properly.

Be tough but fair. This isn’t about pointing fingers—it’s about finding gaps and plugging them. Think of it like prepping for a big game: you want to catch the mistakes in practice, not when the stakes are high.

Step 7: Bring in the Auditors

Alright, it’s go time. You’ll need to hire a certified ISO auditor to check your work. They’re like the health inspector at a restaurant—there to make sure everything’s up to code. They’ll review your processes, interview your team, and maybe even poke around your facilities. It sounds intense, but if you’ve done the prep work, it’s more like a final exam you’ve already studied for.

The audit happens in two stages. First, they’ll review your documentation to make sure it aligns with the ISO standard. Then, they’ll do an on-site visit to see your processes in action. Be honest, be open, and don’t try to hide anything. Auditors aren’t out to get you—they’re there to help you improve.

What If You Don’t Pass?

Don’t panic. If the auditors find issues, they’ll give you a list of “non-conformities” (fancy talk for things you need to fix). Address them, make the changes, and schedule a follow-up. It’s not failure—it’s just part of the journey.

Step 8: Celebrate and Maintain

You did it! The auditor gives you the green light, and you’re officially ISO certified. Pop the champagne (or sparkling water, if that’s your thing) and celebrate with your team. You’ve earned it. But here’s the kicker: ISO isn’t a one-and-done deal. You’ve got to keep those processes tight to maintain your certification.

Set up regular check-ins to make sure you’re still meeting the standard. Think of it like going to the gym—you don’t get fit once and call it a day. You keep showing up. Schedule internal audits, update training, and stay on top of any changes in your industry. In manufacturing, that might mean adapting to new tech. In healthcare, it could be keeping up with patient privacy laws.

Why It’s Worth the Hustle

Getting ISO certified can feel like a marathon, but the finish line is worth it. It’s not just about a fancy certificate to hang on the wall (though that’s nice too). It’s about building a business that’s stronger, more reliable, and ready to take on bigger challenges. Your customers notice. Your employees feel it. And in industries like logistics or IT, where trust is everything, that’s a game-changer.

So, what’s stopping you? Maybe it’s the time, the cost, or just the fear of getting started. But here’s the truth: every step you take toward ISO certification is a step toward a better business. And honestly, who doesn’t want that?