A Raised Design That Sparked a Trend

When a small local brand in Atlanta launched its first streetwear line, they didn’t expect their embroidered caps to go viral on social media. What set them apart? The letters on their logo rose boldly off the fabric — thick, textured, and impossible to ignore. That visual pop was thanks to custom 3D puff embroidery, a technique that’s quietly transforming how apparel communicates brand identity.

If you’re in the apparel or promotional merchandise space, custom puff embroidery can give your designs the edge they need — but only when it’s done right, from stitch planning to digitizing.

What Is Custom 3D Puff Embroidery?

Custom 3D puff embroidery involves stitching over a foam insert that’s placed on the garment before sewing. The design rises off the surface, creating a pronounced, three-dimensional effect. It’s ideal for bold text and large graphic elements that benefit from depth and dimension.

This isn’t just embroidery — it’s sculpted texture that grabs the eye and adds real, tactile appeal to caps, jackets, bags, and more. Customizing this embroidery style allows businesses and creators to shape designs that reflect unique brand identities and stand out from the competition.

Why It’s Gaining Popularity

According to Allied Market Research, the global custom apparel market was valued at $90 billion in 2022 and is expected to reach over $180 billion by 2032. With more brands entering the space, visual differentiation is critical — and puff embroidery does exactly that.

Not only does it look more premium than flat stitching, but it also feels more substantial, which is especially important in today’s market where consumers want tactile, luxury-feel products even in casual wear.

The Power of Customization

With standard embroidery, your design is limited by surface and thread. But with custom 3D puff embroidery, you control:

- The height and density of the puff

- Foam color and thickness

- Stitch angles and sequencing

- Coverage strategy for cleaner edges

This control allows each design to reflect brand personality and garment purpose — whether it’s edgy streetwear, athletic team gear, or high-end promotional items.

The quality of your final product, however, still hinges on precise digitizing. A professional 3D puff embroidery digitizing service ensures that your stitch paths, underlays, and densities are optimized for clean, durable, raised results.

Applications of Custom Puff Embroidery

Custom 3D puff embroidery is used across many industries:

- Streetwear & Urban Fashion: Brands use puffed logos to elevate caps and hoodies.

- Sports Teams: Jerseys and headwear with raised emblems convey team pride.

- Corporate Branding: Custom puff stitching on uniforms and hats signals professionalism.

- Special Events: Embroidered giveaways leave a lasting impression.

- E-commerce Creators: Custom caps with textured logos help products stand out on crowded online marketplaces.

The raised embroidery style not only enhances aesthetics but also helps communicate quality and brand value at a glance.

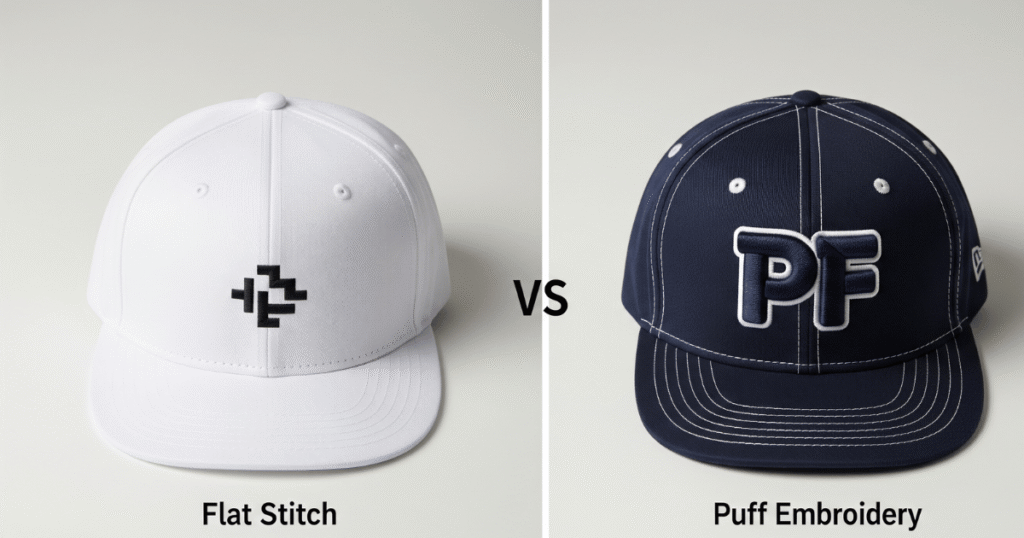

What Makes It Different from Flat Embroidery?

While traditional embroidery lies flush with the fabric, puff embroidery literally stands up. This height adds:

- Greater visibility

- Enhanced dimension in photos

- A more premium, tactile feel

Flat embroidery still works for detailed artwork or small text, but puff embroidery makes the boldest parts of your design unforgettable.

Technical Details Matter

To create an effective puff embroidery file, a digitizer must:

- Use satin stitches wide enough to completely cover the foam

- Adjust pull compensation so the foam isn’t exposed

- Plan a clean exit point to avoid puckering or thread loops

- Account for machine settings based on fabric and foam type

Overlooking even one step can ruin the final result. That’s why professionals rely on experienced digitizing teams to prepare files tailored specifically for puff application, fabric tension, and garment shape.

Conclusion

Custom 3D puff embroidery brings dimension, durability, and visual power to apparel — far beyond what flat embroidery offers. As brands compete for attention in a saturated market, this technique becomes a key differentiator that instantly adds value to your garments.

Are you ready to transform your embroidery designs into bold, elevated statements?